控制系统:触摸屏,PLC可编程序控制器(中德合资)。

气动气缸:¢160mm*60mm=1条(中外合资)。

电磁阀:4V430-C、DC24V=2只 (台湾品牌)。

加温控制系统:温度控制器及固态继电器D24V单相40A(中外合资制造),空气断路器(施耐德)。

热模直线导轨: HGH20*800mm=2根《单工位》(台湾制造)。

上下活动治具板:400mm*650mm*25mm(铁板镀铬)。

上下活动直线轴承¢25mm=4只,光轴¢25mm *(530mm-600mm)=4根(台湾制造)。

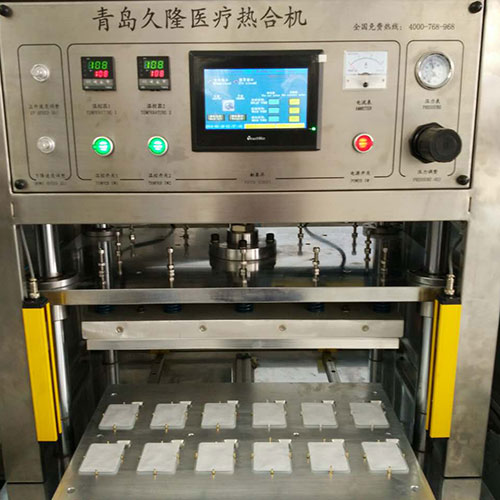

机架尺寸部分; 900mm*600mm*1600mm 设备外壳采用304不锈钢材质。

生产范围

吻合器车间无菌包装,二类、三类医疗器械及药品阻菌包装。

参考和依据的标准和规范

安全:依照国家标准。

所有的电气设备和电缆必须根据国家相关标准或其他标准,适合于无菌制药洁净区域并符合工艺说明要求。

材质要求

设备外壳采用304不锈钢材质,机体内部材质采用日本SKD-61模具钢。

表面处理

设备内部钢板表面镀铬,以防对产品造成污染。

模具尺寸按需方图纸要求,材料采用7075美铝工艺的模具,做出完善的产品包装,以达到阻菌、剥离、渗透好的效果。

设备技术要求:

设备能满足透析纸、特卫强、PVC、APET、GAG,PET(PETG)等环保材料的吸塑盒与特卫强涂胶纸(医用透析纸)或医用包装材料的粘合。

透析纸用途:用于包装医疗器械进行灭菌,透析纸的好处是可以进出蒸汽,但不透水.医用透析纸;医用涂胶专用透析纸;输液器,注射器吸塑包装热合专用设备。医用透析纸,涂布层热合温度在105摄氏度左右,热合速度5-12秒,压力0.4Mpa,就可以达到每15mm剥离拉力不小于1.5N。提高了产品的品质,产品符合EN868标准.

在模具的有效压合面内,保障热封均匀,接触良好,平整无褶皱。

模具温控应保障在温差在±1℃。

气缸动作须上下流畅,无阻滞现象。

在热合过程中需保障上下模具热合平面平行。

配套模具采用美铝7075铝合金材质,表面做特氟龙涂层处理。

售后服务

设备保修期为1年,保修期内设备电子零部件如出现质量问题均由供方负责,更换或维修,并免费更换零部件。

久隆设备说明及注意事项:

型号:JL-5000D 医疗吸塑封口机

使用电源:AC220V 功率6KW。

使用气源:0.8MPa 1立方空压机。

控制系统:触摸屏、PLC(可编程控制器)。

熔接面积:600mm×350mm。

机台尺寸:900mm×600mm×1600mm。

机台重量:280KG.

操作准备:

连接气源,使压力表批示0.3~0.8MPa,

检查气源是否漏气。

连接适当的电源,打开单相电源开关,再

打开加热开关,使加热模开始升温到设定的温

度,开始恒温。

当加热模的气缸升到起始位置,在手动位

置时,按触摸屏上的各手动开关,既可进行手

动操作。

模具的安装,在手动画面上,,滑台推进后

按两个绿色按钮,手点式设计,方便对位。

使用说明:

机器底部右下方门打开,有3组电源开关, 组为控制电路开关,第二、第三组是机器发热电源开关。

只有机器底部的 组电源开关开启以后,才能打开机器正面上部面板上的电源开关,调整温度仪的设置。

在“手动操作控制”运行,双手按钮的功能,可以调模、试模;

在“自动操作控制”运行,滑台推入接触到微动开关,可以自动完成整个工作流程。

“自动操作控制”运行按钮,当滑台推动前,请在手动状态时,将气缸升到顶部,方可自动运行,这是为了磁控开关给一个初始信号。

“自动操作控制”运行里还有热模的当前实际温度显示,和本班生产产品的个数,在当班个数的后面可以看到‘清零’按钮。

在“手动操作控制”运行按钮(机器侧面的有3个按钮,绿色的为双手点动按钮),在双手手动操作的情况下点击按钮,会点动下降,点动中间的红色按钮,回点动上升。

热熔时间设置,热熔时间是从热模开始下降到开始上升的时间。

在热模温度控制方框中,PV为当前实际温度不可以修改,SV为要设置热模需要的温度值可以修改。

在手动模式下同时按下两个绿色按钮,机器可以自动启动。

在自动模式下同时推入滑台,机器可以自动启动。

注意事项:

由于机器的震动,有可能会使温度传感器的连接线变的松动,所以要定期检修一下是不是连接处有松动。

在自动情况下启动机器时,必须要保障上模到达信号开关。

操作员在自动的情况下手不能伸入模具底部,防止热合时压倒。

服务热线service

服务热线service